How Small Apertures Can Laser Drilling Machines Drill?

Laser drilling machine is a general name for laser equipment used to drill holes on the surface of materials. Laser drilling machine can refer to both laser marking machine and laser cutting machine. Its drilling principle is to use the laser output high-voltage heat source laser beam to focus on the surface of the workpiece, so that the workpiece melts instantly and forms a hole shape. It can be used to punch small holes and micro holes in various metals, non-metals and composite materials. As for the size of the hole and the thickness of the material that the laser drilling machine can drill, I will explain it to you in detail today.

Compared with traditional EDM drilling and mechanical drilling equipment, laser drilling has higher drilling accuracy and better drilling quality. The drilling is more smooth, without burrs and burrs around, and more uniform; there is no limit to the processing material, and it can be used for non-deformation drilling of any hardness material such as steel plate, stainless steel, aluminum alloy plate, and hard alloy. Able to achieve hole: 1.00~3.00 (mm), sub-small hole: 0.40~1.00 (mm), ultra-small hole: 0.1~0.40 (mm), micro hole: 0.01~0.10 (mm), sub-micro hole: 0.001~0.01 (mm), ultra-micro hole: 0.001 (mm) and other specifications for drilling holes. Of course, different models need to be selected to achieve different hole diameters.

The laser drilling machine is used to reduce the diameter of the spot to the micron level to obtain high laser power density. Ultra-high power density lasers can laser drill holes in almost any material. Laser drilling emphasizes no burrs, high efficiency, and fineness. How small the hole can be drilled by the laser depends on the material itself. Generally, the thickness of the material also determines the size of the punching hole. The thinner the material, the lower the requirements for the machine, and the finer the punching. For metal products, 5-8mm holes can be punched on it; otherwise, the thicker the material, The higher the requirements for the machine, the more expensive the machine will be.

Compared with the traditional process, laser drilling has significant technical advantages, and has the characteristics of fast drilling speed, high efficiency, and good economic benefits. It is a vacuum non-touch processing, which not only effectively avoids scratching the workpiece, but also reduces the cost of mold manufacturing. It uses its own tracking sensor system to effectively maintain the height of the workpiece, allowing the laser to process on irregular surfaces (inclined surfaces, diamond-shaped surfaces, etc.) without affecting the ratio of depth to diameter. The laser drilling machine is also a fully automatic processing equipment, and one person can take care of several devices; the processing will not cause pollution and harm; the equipment is equipped with an alarm system, which guarantees safety; the cooling effect is good, and the photoelectric conversion efficiency is high. It is the most mature and stable punching device.

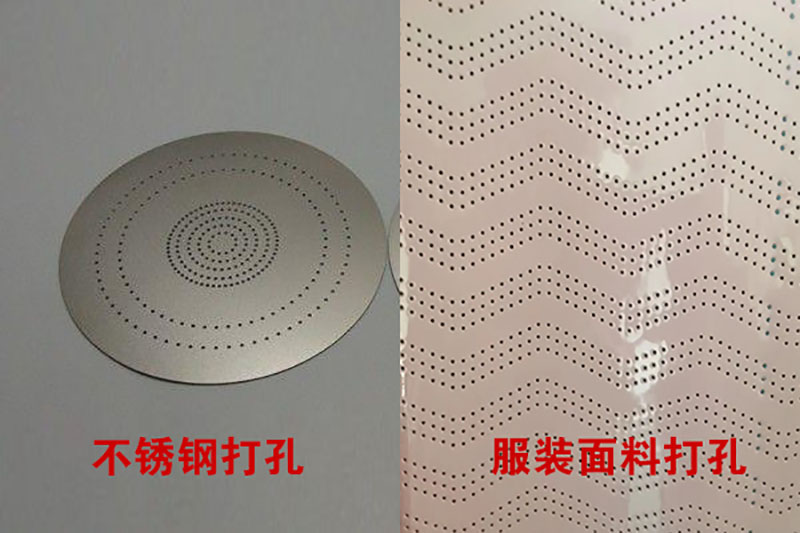

Recommended model: fabric laser punching machine